Dry Ice Blasting

3/23/2021 (Permalink)

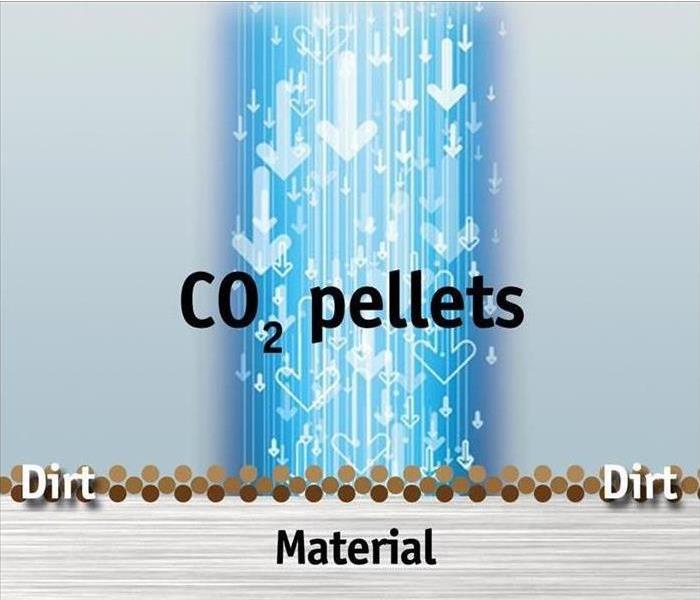

Dry ice blasting is a revolutionary blasting method that uses dry ice pellets (CO2 in solid form) as the blasting material. The process is very environmentally friendly and provides a fast and effective alternative to traditional methods of cleaning. Dry ice blasting is one of the best ways to restore properties that have smoke or fire damage. Dry Ice blasting is ideal for the restoration of wood, concrete, brick and building materials because it’s fast, dries instantly and leaves little or no residue. It is very efficient with the removal of smoke, mildew, smell, mold and other damages without causing deterioration of the surface.

A faster and more effective process for remediation and restoration

KEY ADVANTAGES TO ICE BLASTING

A Dry Cleaning Process: Dry ice blasting is a completely dry process because dry ice pellets consist of CO2 and vaporize immediately on contact with the surface to be cleaned.

No Waste Disposal: The system produces no waste products. Only the coating that has been removed remains to be disposed of, and this can usually be swept or vacuumed from the floor.

Environmentally Friendly: Dry ice blasting is completely non-toxic and no hazardous chemicals are used. Costs connected with the disposal of blasting materials and solvents are saved.

No Abrasion: Dry ice blasting is non-abrasive and therefore surfaces are treated very gently. Wear and tear resulting from the use of steel brushes, scrapers and other blasting materials is avoided.

Improved Production Quality: Dry ice blasting often allows for your production equipment to be cleaned while in operation without a need for dismantling or costly downtime.

Learn how our team is here to help with this revolutionary technology!

24/7 Emergency Service

24/7 Emergency Service